Dec 21 2024

/

Zinc Coaxial Cable vs Copper Coaxial Cable: A Detailed Comparison

Zinc Coax vs. Copper Coaxial Cable: Choosing the right cable is crucial for optimizing the performance of your communication systems. When evaluating these options, it’s important to weigh factors like material properties, conductivity, cost, and application suitability. Whether you’re a manufacturer refining your product lineup or a tech enthusiast exploring coaxial cable technology, this guide breaks down the essential details to help you make an informed decision.

What Are Zinc and Copper Coaxial Cables?

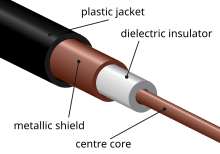

Coaxial cables deliver signals efficiently thanks to their conductive materials. Copper has long been the gold standard. While zinc isn’t commonly found as a primary conductor in coaxial cables, its role as a coating material to enhance durability has sparked confusion about its applications.

Zinc coaxial cables typically refer to cables with a zinc coating or layers added to protect the core material, while copper coaxial cables are primarily made of copper, known for its high conductivity.

With this clarified, let’s break down the differences and applications more thoroughly.

Material Properties

Copper Coaxial Cable

- Conductivity: Copper is widely regarded as an exceptional conductor, boasting high conductivity that ensures minimal signal loss.

- Strength and Flexibility: Copper’s mechanical strength and pliability make it an ideal material for installations requiring bending or routing.

- Reliability: Copper resists oxidation especially when treated, making it durable for long-term usage.

Zinc Coaxial Cable

- Conductivity: Zinc is significantly less conductive than copper, roughly six times less efficient, which can limit its signal transmission capabilities.

- Role as a Coating: Zinc is mainly used for its corrosion resistance. It’s applied as a protective layer to extend the lifespan of cables in outdoor or harsh environments.

- Durability: While zinc coatings can reduce oxidation, long-term exposure to weather can cause the zinc to powder over time, possibly requiring maintenance.

🛠 Verdict: Copper comes out on top as the superior material for conductivity and mechanical performance, though zinc serves well as a protective layer in industrial or outdoor settings.

Performance Comparison

1. Conductivity

- Copper’s conductivity outshines zinc by a large margin, making it the better choice for transmitting signals efficiently. Lower resistance means lower energy loss during transmission, which is crucial for high-frequency applications.

2. Signal Attenuation

- Copper coaxial cables maintain stable signal strength over long distances, minimizing attenuation.

- Zinc-coated cables, while more resistant to certain environmental factors, are outperformed in maintaining signal quality.

3. Durability and Corrosion Resistance

- Pure copper cables are long-lasting and often treated to improve oxidation resistance.

- Zinc-coated cables provide durability in challenging outdoor environments like coastal areas or chemical plants but aren’t designed for optimal performance over extended periods.

4. Interference Resistance

- Both materials, with proper shielding, can resist electromagnetic interference (EMI). However, copper’s superior conductivity improves its shielding efficiency.

🛠 Verdict: For critical applications requiring stable, high-bandwidth operation, copper excels. Zinc provides strong environmental protection but lacks the signal quality of copper.

Application Scenarios

Best Uses for Copper Coaxial Cables

- Television Broadcasting

- Satellite Communications

- Closed-Circuit Television (CCTV) Systems

- High-Speed Computer Networks

Copper coaxial cables are ideal for applications where high-quality signal transmission is non-negotiable. Their superior conductivity ensures optimal performance for demanding communication technologies.

Best Uses for Zinc Coaxial Cables

- Outdoor Environments (e.g., humid or corrosive conditions like near the seaside)

- Chemical Plants or similar industrial applications require enhanced corrosion protection.

Zinc-coated cables are better suited where environmental durability is prioritized over transmission quality.

Cost Considerations

Copper is an expensive material compared to zinc. While this increases the upfront cost of copper coaxial cables, their superior performance, reliability, and lifespan often justify the investment.

Zinc-coated cables, on the other hand, are typically more affordable but may result in increased long-term costs due to performance trade-offs and potential maintenance requirements.

For most professional and commercial applications, the enhanced performance of copper outweighs the initial price difference. However, budget-sensitive projects with less stringent performance requirements might consider zinc-coated options.

How to Decide Between Copper and Zinc Coaxial Cables

Selecting the right coaxial cable depends on your project’s needs. Ask yourself these questions to guide your decision-making process:

- Do I need the best possible signal quality? Choose copper.

- Is my project focused on an outdoor or corrosive environment? Consider zinc-coated cables.

- What is my budget? Factor in both upfront cost and long-term maintenance.

Final Thoughts

Regarding zinc coaxial cable vs copper coaxial cable, each has its place depending on the application. Copper is the superior choice for high-performance communication, thanks to its exceptional conductivity and reliability. Zinc shines as a protective layer, ideal for environments that demand corrosion resistance.

Carefully evaluate your needs, budget, and environmental conditions before making your final decision. High-performance systems rely on the right materials, and understanding their differences ensures you’re equipped for success.

Frequently Asked Questions

1. What is the main advantage of copper coaxial cables over zinc-coated cables?

Copper coaxial cables offer superior signal quality due to their high conductivity and low resistance. They excel in applications requiring high bandwidth and reliable performance.

2. Is zinc coaxial cable commonly used?

Coaxial cables made entirely of zinc are extremely rare. The term “zinc coaxial cable” often references cables with a zinc-coated layer, designed for corrosion resistance rather than optimal conductivity.

3. Can zinc-coated cables replace copper cables?

Not entirely. Zinc-coated cables can work in specific environments like outdoor or industrial settings but aren’t suitable for applications requiring high-quality signal transmission.

4. Are copper coaxial cables worth the higher cost?

Yes, copper cables provide better value over time for applications needing high performance and signal integrity over long distances despite the higher initial cost.

5. Can these cables be used interchangeably?

No, the choice depends on your specific requirements. Copper is ideal for high-performance scenarios, while zinc coatings are better for environmental durability.